Painting

Car body cleaning

Cleaning systems are used to remove loose dust and particles of dirt from vehicle bodies before they are painted. Dürr's tried-and-tested machines and innovative robot-controlled systems can significantly improve the first run rate.

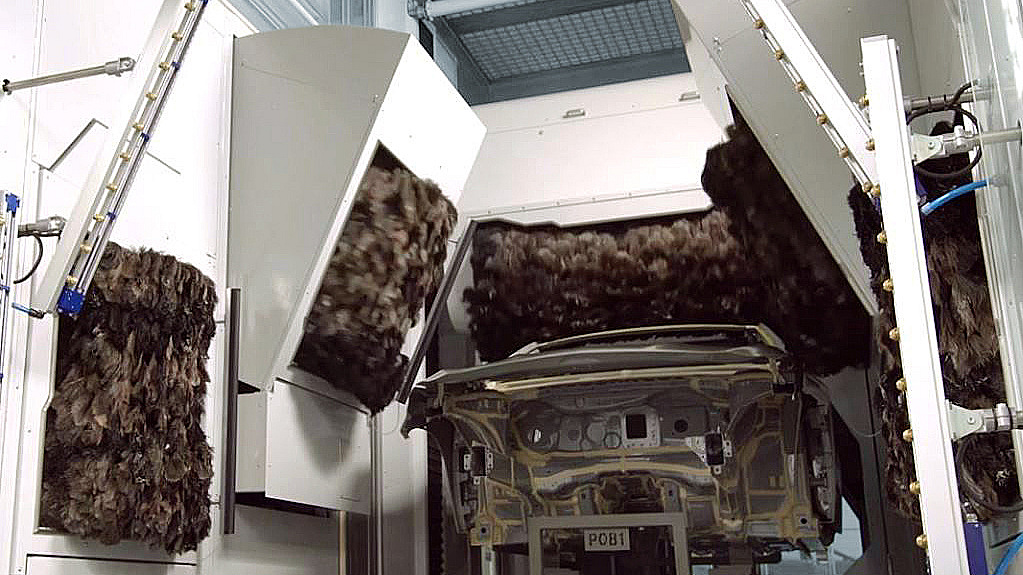

Soft, reliable, and flexible: Dürr has been supplying its fully automated machines for cleaning the outside of vehicle bodies since the end of the 1980s. The EcoClean systems are long-term bestsellers that are in use worldwide. Their special feature is their ostrich feathers, which do an extremely thorough job of removing loose dust and particles of dirt before the painting process. This significantly improves the first run rate.

Consistent quality and performance: The EcoRS Clean Brush system consists of a robot fitted with sword brushes which clean the outside of vehicle bodies particularly gently and reliably. The brushes are integrated into the manufacturing process and provide reproducible cleaning results in stop & go and in rail tracking operation.

Thorough preparation is an essential part of a high-quality paint application process. The EcoBlow-Off cleaning system removes dust and dirt from the inside of vehicle bodies and cleans the outside before they are painted. It is the perfect complement to the EcoClean external cleaning system with its feather rollers.

Ideal for complex body contours and a wide range of models, the EcoRS Clean F combines efficient cleaning using feather rollers with the high flexibility of a robot. This is because the robot cleans different body shapes efficiently and independently of each other in almost any combination and sequence. It is designed for vehicle sizes up to 2.0 m in height and width and is suitable for line tracking and stop-and-go operation. The modular cleaning cells can be planned with a variable number of robots in order to achieve the right surface performance level as appropriate to the body size and available cycle time.

FeatherDuster

The FeatherDuster system advances vehicle paint lines by replacing purpose-built “tack off” machines with robotic technology that is incredibly flexible and built on well-established standards to achieve higher quality, efficiency and ease of use.

Traditionally, purpose built “tack-off” machines have handled the painstaking task of removing dust and dirt particles from a vehicle before it is painted on an assembly line. ABB’s FeatherDuster system replaces these one-dimensional machines with an unheard of level of precision, control and flexibility by combining a standard ABB robot with an advanced rotating feather and vacuum tool to suck particles from the surface of the vehicle.

Easy programming and control

The FeatherDuster is controlled through ABB’s simple, familiar and time-tested user interface. Via the FlexPendant attached to the IRC5 Controller, users can program the entire cleaning cycle without the need for any additional software tools. In addition, PC-based virtual programing and simulation with ABB’s RobotStudio software saves time and allows fast path generation, simple setup, and robust backup/restore at a click of the mouse.

Reliable performance with high-quality production

Unique 3D control of the duster head in complete synchronization with the movement of the conveyor leads to more precise and thorough cleaning.

FeatherDuster can follow the contours of the car’s shape and conduct cleaning in a more efficient manner. The system’s rotating feathers clean dust from the surface, which is then sucked from the feathers by a vacuum. With each rotation, the feathers are de-ionized to release the dust and prepare for another pass over the vehicle surface.

A compact, flexible and efficient solution

The robotic cleaning system has a much smaller footprint than traditional solutions and fits any station layout making it simple and quick to integrate into new or existing paint lines. The FeatherDuster system has fewer rollers and a lower vacuum requirement than purpose-built tack-off machines, meaning it consumes less energy and further adds to your company’s bottom line.

Smart investment

ABB offers a cost-effective solution that is scalable with 2 or 3 robots based on the required conveyor speed. The system can also be easily reprogrammed as new models of all sizes are introduced to the line, without the need for specialists. Because it relies on well-established and time-tested robotic technology, FeatherDuster has incredible uptime and reliability. When it does need servicing, replacement parts are easy to come by and can be delivered very quickly to ensure a minimum of down time.

Features and benefits:

-

Compact design; very small factory floor footprint

-

Low investment cost and high energy efficiency

-

Precise and flexible movement for effective cleaning

-

High reliability (MTBF> 50,000 h), easy maintenance

-

Modular design and convenient/fast installation

-

Easy programming and control with familiar, time-tested tools

- Stop & go

- Tracking

- 3C2B

- 3C1B

- Primerless

- Online checking

- Off-line checking

- Smart ray