Fuid Control System

Function

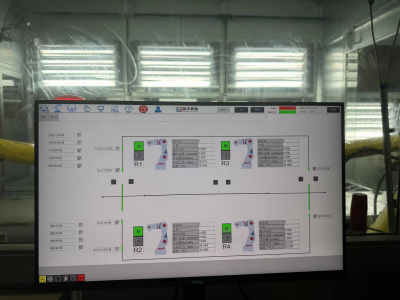

The Wax Injection Control System by JetGlow is a state-of-the-art solution designed to optimize the wax application process by maintaining a consistent wax flow. It automatically adjusts key parameters in real-time to adapt to environmental changes, ensuring steady and uniform wax application.

Industries

This system is particularly suited for automotive manufacturing, where precision and consistency are essential. It is ideal for use in environments where wax application quality must be maintained, despite varying production conditions.

Advantages

• Rapid Adjustment: The system adjusts to slight changes in environmental conditions within 0.05 seconds, and significant changes within 0.38 seconds, ensuring minimal production disruption.

• Viscosity Management: This function continuously monitors temperature-related viscosity changes and adjusts wax outlet pressure to maintain consistent flow, ensuring uniform application.

• Increased Efficiency: By reducing the need for manual intervention and eliminating frequent production stoppages, the system enhances operational efficiency and reduces costs.

How It Works

1. Real-Time Parameter Adjustment: The system dynamically adjusts wax outlet pressure using real-time feedback from flow meters to maintain consistent application.

2. Viscosity Monitoring: It continuously monitors wax viscosity, which is highly sensitive to temperature changes, ensuring even and effective wax application.

3. Predictive Adaptability: The system uses predictive algorithms to anticipate changes in viscosity and environmental conditions, making adjustments autonomously without requiring manual input.