Slef-adaptive Spray Path Generation System

Function

JetGlow's Self-Adaptive Spray Path Generation System automates the spray path process, reducing setup time and minimizing human error. It is designed to deliver precise, efficient coating solutions for applications requiring high accuracy, ensuring consistent quality with minimal waste.

Industries

This system is well-suited for military and aerospace applications, where precision is crucial. It is ideal for valuable workpieces, low production volumes, and high testing costs, providing an efficient alternative to manual programming.

Advantages

• Elimination of Manual Programming: The system removes the need for time-consuming manual programming, offering a more efficient and error-free setup process.

• High Precision: Our system ensures that every workpiece is coated with the exact amount of paint needed, minimizing waste and maximizing efficiency.

• User-Friendly Operation: By automating complex calculations and path generation, the system allows operators to focus on other critical tasks, improving overall productivity.

• Versatility: The system’s ability to adapt to different workpieces and requirements makes it a versatile tool in various high-stakes industries, providing consistent quality across different projects.

• Real-Time Monitoring and Adjustment: The system's integration of sensors and cameras enables real-time monitoring, allowing for adaptive changes to maintain consistent quality and reduce the risk of errors.

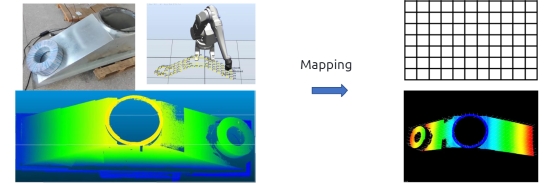

How It Works

1. Grid Setup: The system begins by setting a grid size that corresponds to the required spray distance and the dimensions of the workpiece. The grid ensures that the spray pattern is comprehensive and consistent, covering every necessary area without gaps.

2. Alignment Calculation: At each path point, the system calculates the normal vector to ensure that the spray gun is properly aligned with the workpiece during spraying. This process ensures that the spray is always at the optimal angle, maintaining even coverage, reducing overspray, and improving coating quality.

3. Real-Time Adjustment: The system uses sensors and cameras to monitor the workpiece in real-time, making automatic adjustments to the spray path as needed. This feature helps compensate for any variations in workpiece shape or position, ensuring consistent results across different components.

4. Adaptive Path Optimization: Based on the real-time data, the system continuously optimizes the spray path to achieve maximum efficiency and quality. This reduces paint usage and minimizes waste, further enhancing the cost-effectiveness of the process.