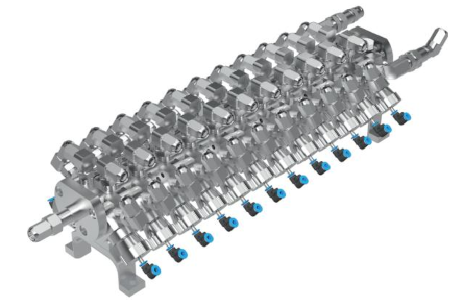

Color Changer

Valve cores:

Material options: Polymer / Stainless steel;Select the appropriate core material based on paint properties.

The valve must feature precise actuation and rapid response time to ensure minimal cycle durations for robotic color change and cleaning operations.

Valve Seat:

Material options: Polymer / Stainless steel;Select the appropriate material based on paint characteristics.

The seat requires an ergonomic design and lightweight construction to facilitate integration onto robotic arms. The paint channels must be dead-angle-free to enhance robotic automated cleaning efficiency.